-40%

CNC Kit 4Axis Breakout Board&Nema17 Stepper Motor For DIY Router/Mill/Plasma 24V

$ 63.96

- Description

- Size Guide

Description

Store categorySign Up Now !

You may also like

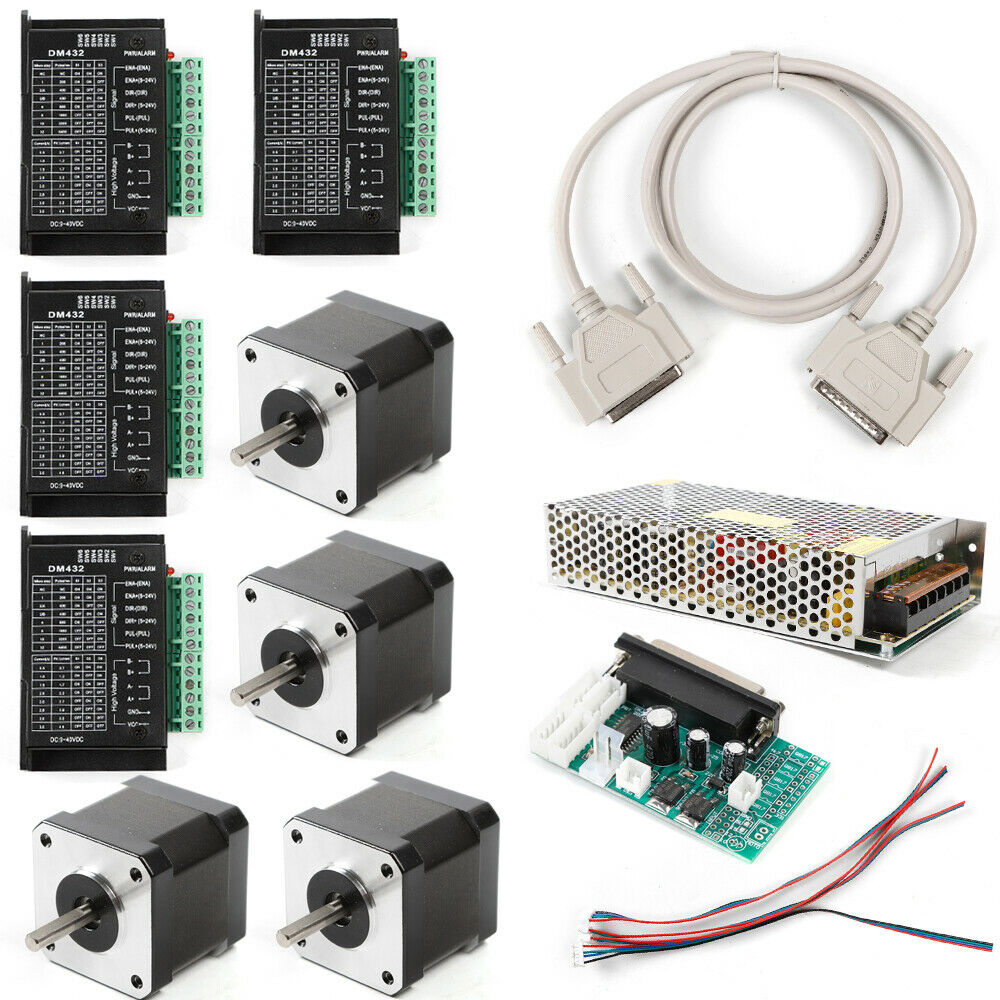

【USA free】4 Axis Nema17 Stepper motor 48oz-in 40mm 1.7A & DM432 Driver CNC Kit

Product Description

Features:

1.High torque, More smooth movement

2.High efficiency, energy-saving, low noise, low vibration, high start torque, low start current and reliable performance.

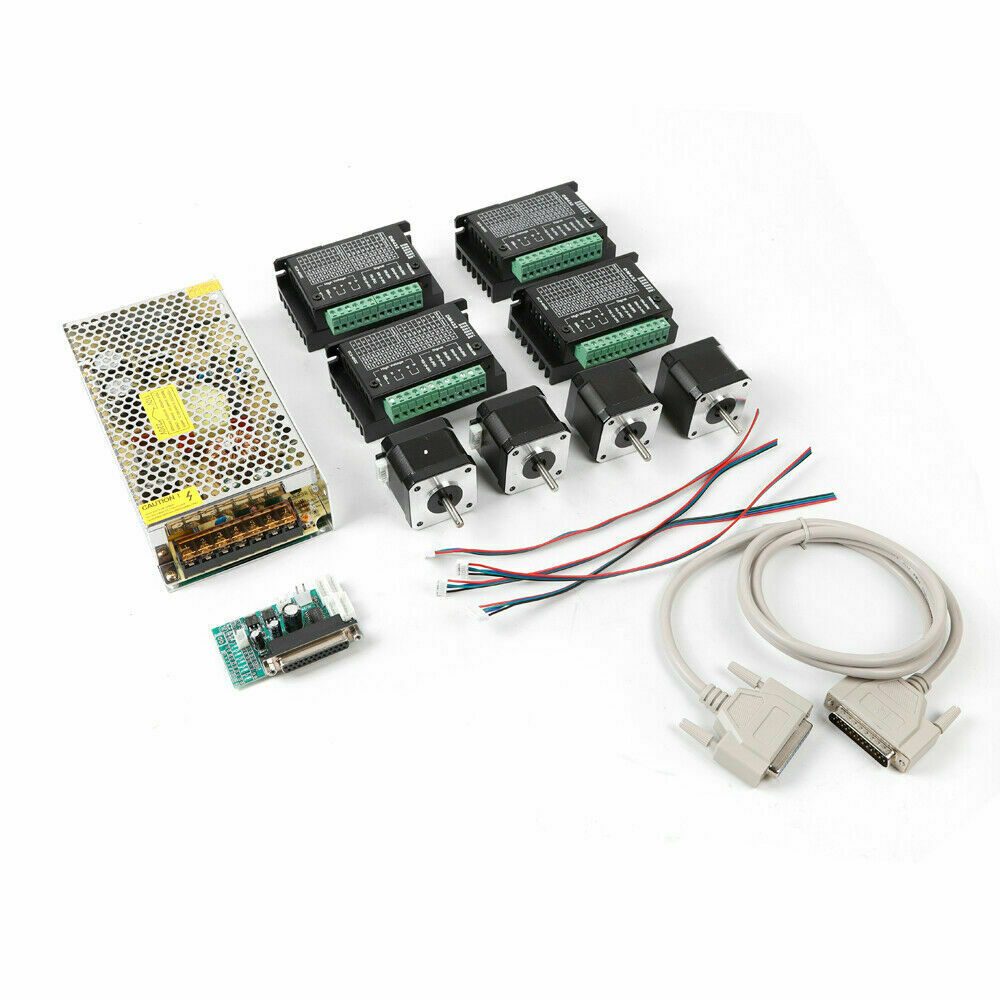

This item includes:

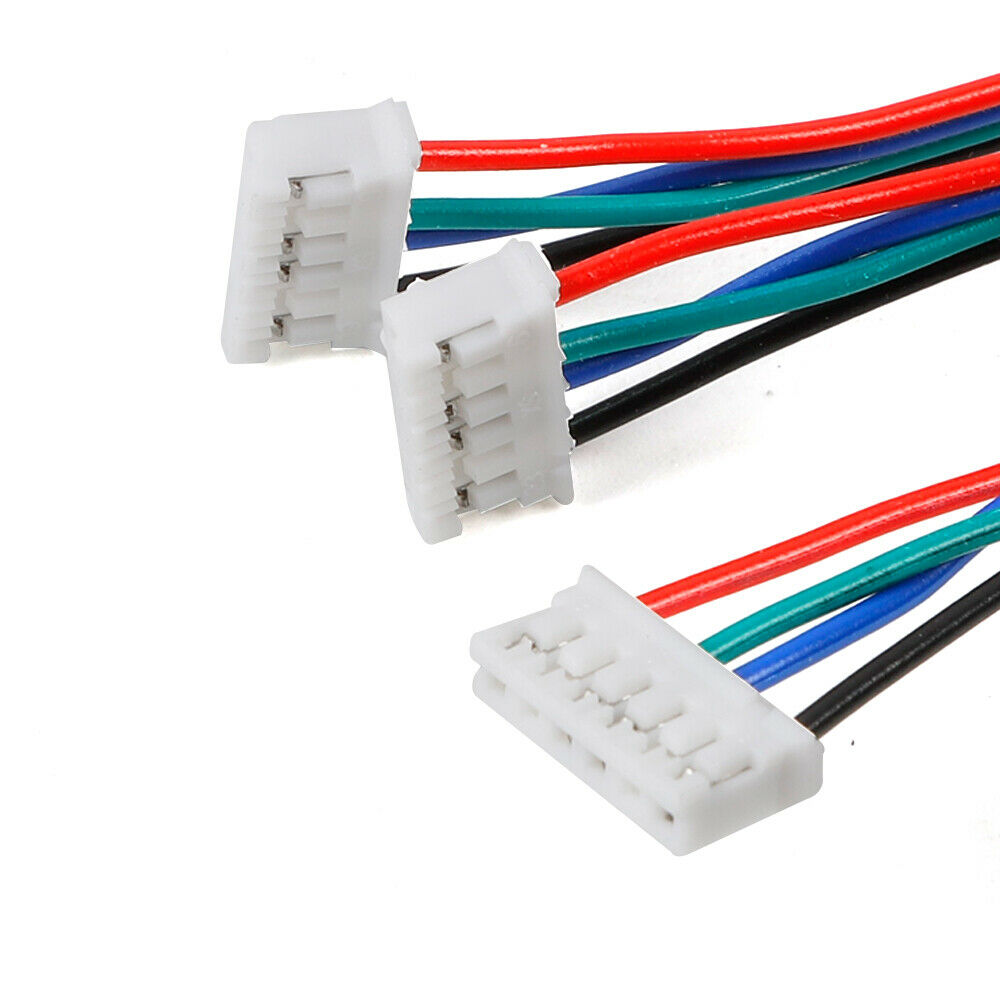

4 pcs Nema 17 stepper motor with

48

oz. in=4Kg.cm,4 leads, 1.7A

4 pcs Stepper motor driver DM

432

, peak

3.5

A,

32micsteps

1 pc Power supply 200W-24V

1 pc breakout board & 1 pc parallal cable

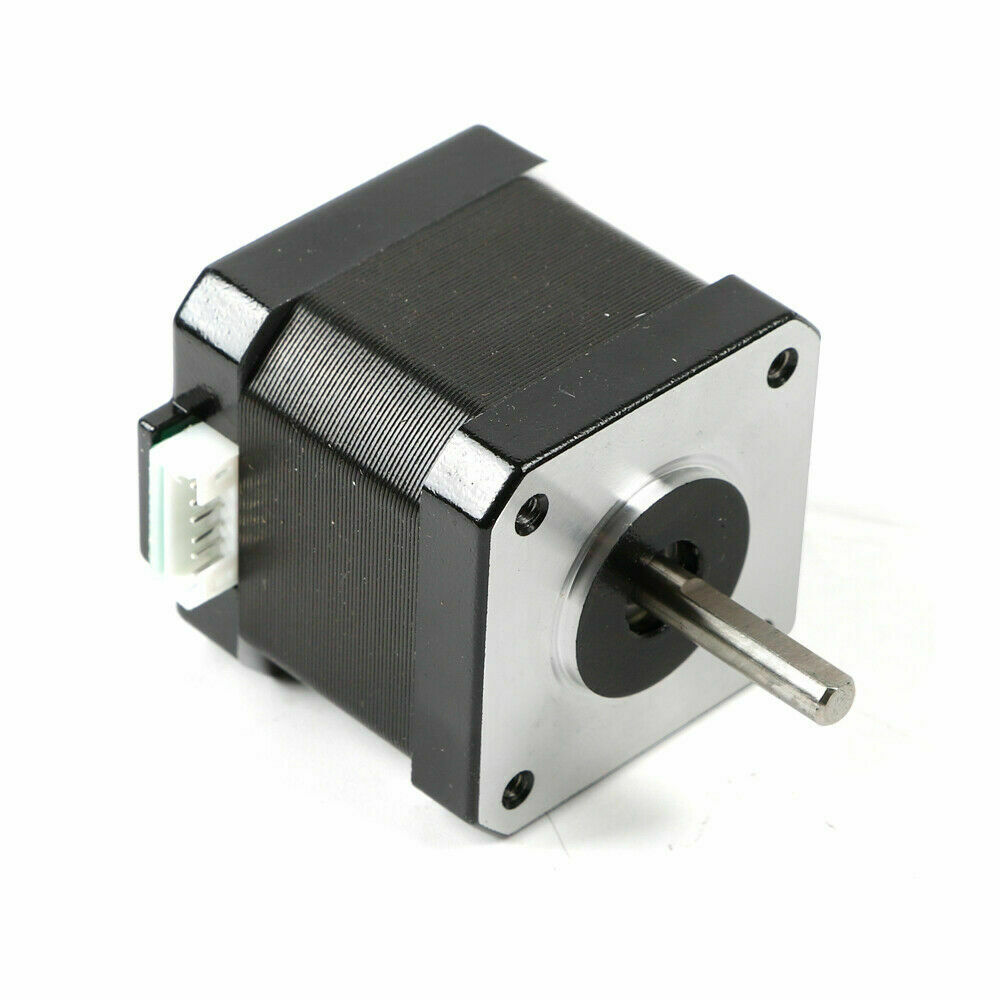

1. Nema 17 stepper motor:

Technical Specifications

Frame Size: NEMA23

Phase: 2 Phase

Step Angle: 1.8 degree

Current:

1.7 A

Rated Voltage: 2.55 V

Resistance: 1.5Ohm/phase

Inductance: 2.8 mH/phase

Holding torque: 48 oz-in (0.40N.m 4000G-cm=40N.cm)

Detent torque: 2.2 N.cm

Rotor inertia: 54 g.cm²

Number of wire leads: 4 (Black A+ ,Green A- ,Red B+ ,Blue B-)

Length: 40 mm

Matched drive:

DM4

32

Shaft:

Single Shaft

Front shaft length

:

24mm

The diameter for motor shaft is

:

5mm

The diameter of axle is 5mm and the length of the shaft is 24mm.

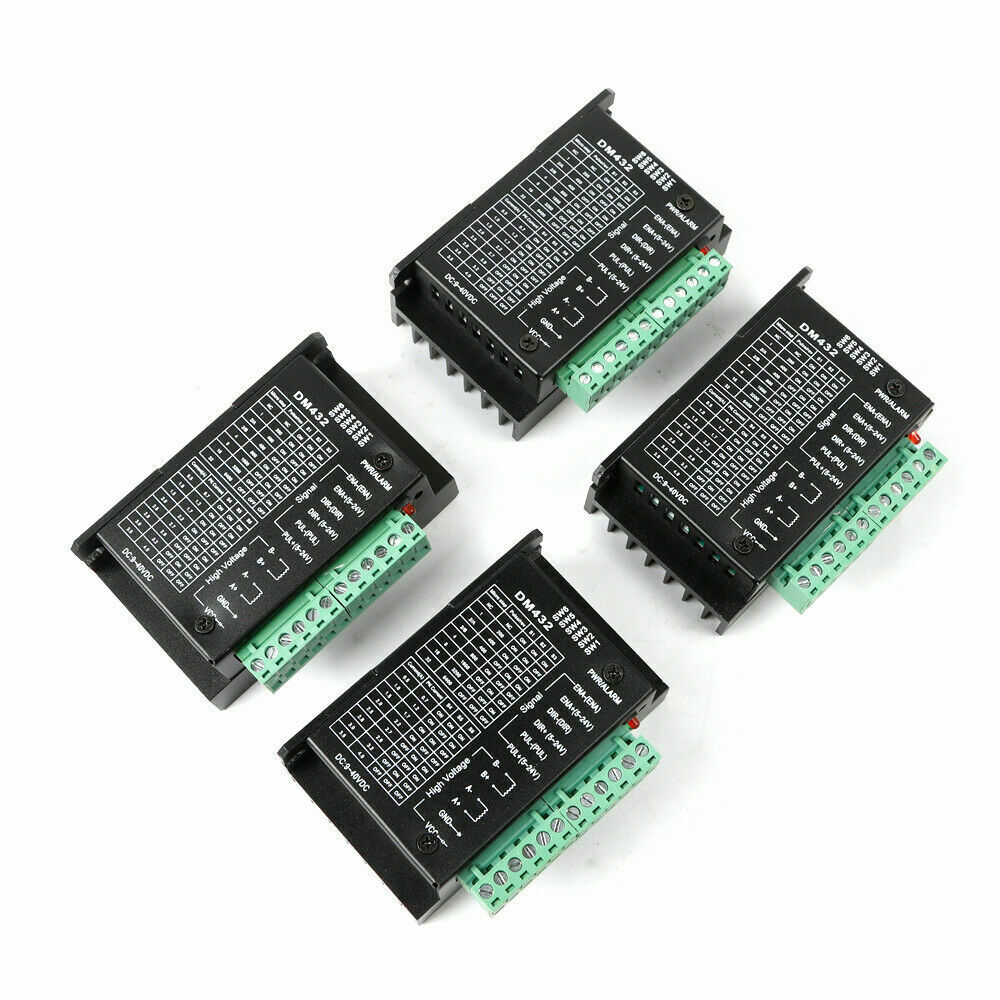

2. Stepper motor driver DM432, peak 3.5A, 32 micstep

Features:

l High performance, low price

l Average current control, 2-phase

s

tepper motor drive

l Supply voltage from

9

VDC to

40

VDC

l Opto-isolated signal I/O

l Overvoltage, under voltage, overcorrect, phase short circuit protection

l

7

channels subdivision and automatic idle-current reduction

l 8 channels output phase current setting

l Offline command input terminal

l Motor torque is related with speed, but not related with step/revolution

l High start speed

l High hording torque under high speed

Electrical specification:

Input voltage

9

-

40

VDC

Input current

<

5

A

Output current

0.

5

A-

4

A

Consumption

Consumption:

16

0W;

Temperature

Working Temperature -10~45℃;

Stocking temperature -40℃~70℃

Humidity

Not condensation, no water droplets

gas

Prohibition of combustible gases and conductive dust

weight

20

0G

Connector Pins Configurations

Pin Function

Details

PUL +,PUL-

Pulse signal, PUL+ is the positive end of pulses input pin

PUL- is the negative end of pulse input pin

DIR+,DIR-

DIR signal: DIR+ is the positive end of direction input pin

DIR- is the negative end of direction input pin

EN+

EN+ is the positive end of

Motor offline control.

EN-

EN- is the negative end of

Motor offline control

Function choice

( Using DIP pins to achieve this function)

1

)

Subdivision setting:

Dip switches 1, 2, and 3 correspond to S1, S2, and S3, respectively.

S1

S2

S3

Pulse/rev

Micro

ON

ON

ON

NC

NC

O

N

ON

O

FF

200

1

ON

OFF

ON

400

2/

A

OFF

O

N

ON

400

2/B

ON

O

FF

OFF

800

4

OFF

ON

OFF

1600

8

O

FF

OFF

O

N

3200

16

OFF

OFF

OFF

6400

32

2

)

Current setting

:

Dip switches

4

,

5

, and

6

correspond to S

4

, S

5

, and S

6

, respectively.

S

4

S

5

S

6

Cuurent(A)

ON

ON

ON

0.

5

ON

OFF

ON

1.0

ON

ON

OFF

1.5

ON

OFF

OFF

2.0

OFF

ON

ON

2.5

OFF

OFF

ON

2.8

OFF

ON

OFF

3.0

OFF

OFF

OFF

3.5

3

) Troubles

Alarm indicator

Reasons

Measures

LED off turn

Wrong connection for power

Check wiring of power

Low-voltages for power

Enlarge voltage of power

Motor doesn’t run, without holding torque

Wrong connection of stepper motor

Correct its wiring

RESET signal is effective when offline

Make RESET ineffective

Motor doesn’t run, butmaintains holding torque

Without input pulse signal

Adjust PMW & signal level

Motor runs wrong direction

Wrong wires’ connection

Change connection for any of 2 wires

Wrong input direction signal

Change direction setting

Motor’s holding torque is too small

Too small relative to current setting

Correct rated current setting

Acceleration is too fast

Reduce the acceleration

Motor stalls

Rule out mechanical failure

Driver does not match with the motor

Change a suitable driver

3. Power supply 200W-24V

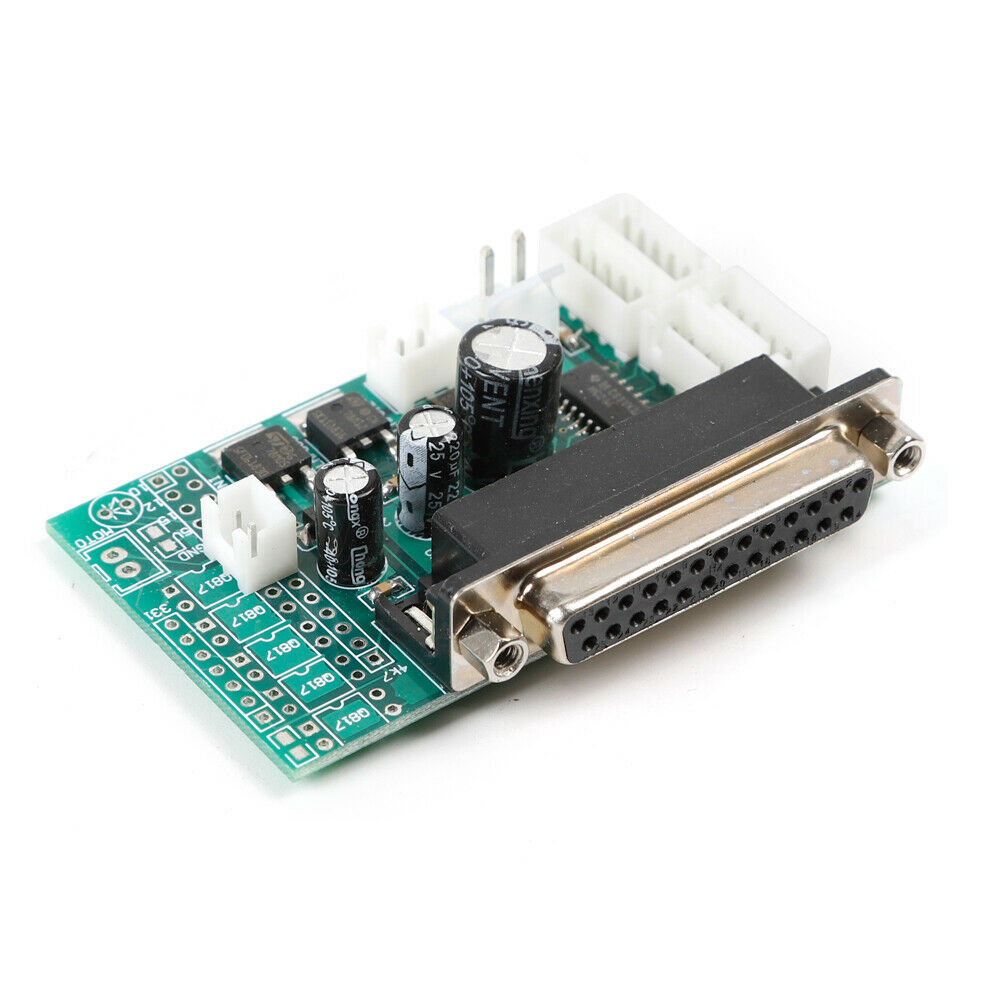

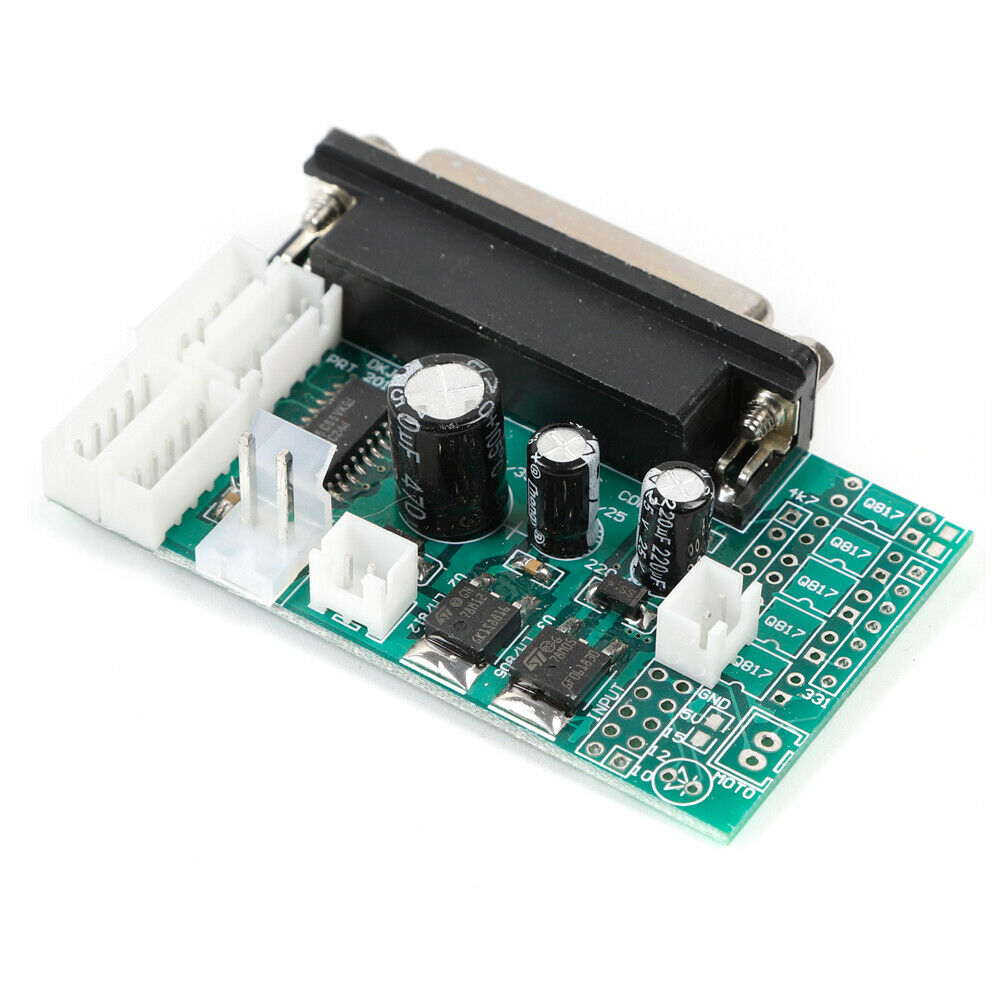

4. breakout board

Built in DB25 male connector.

DB25 Output Pin:P1,P2,P3,P4,P5,P6,P7,P8,P9,P14,P16,P17.

DB25 Input Pin: P10,P11,P12,P13,P15.

DB25 GND Pin: P18-P25.

Power supply: +5V DC.

Built in C-class Optical-coupler.

General in the software

P2 P3 is set to X-axis for the X-axis pulse

P4 P5 is set to Y-axis, Y axis pulse

P6 P7 is set to Z-axis Z-axis pulse

The other can be set to A B C axis

A-axis pulse P8 P9 is set as the A axis

P14 is set to B-axis B-axis pulse P1

P16 P17 is set to C-axis, C axis pulse

Can also be set to the spindle control signal \ electrical permit

Input interface for the P10 P11 P12 P13 P15

Application:Our Stepper Motors are used on small to mid-sized CNC mills or milling machines, CNC lathes, Pick-n-place machines,Laser Engravers and Laser Cutters, Vinyl Sign Cutters, CNC Plasma Cutters, and CNC Foam Cutters. Carver machine ,Dispenser,Automazation,3D Printer,Stage lighting,instrument,laser equipment,scanner and so on.These motors have been used in precision telescope positioning systems and robots.

Payment

Delivery details

Terms of sales

About us

Contact us

Payment

We accept ebay payment 。

Fees such as import duties, taxes are not included in the item price or shipping costs. These charges are the buyer's responsibility.

Delivery details

Shipping:

The item will be shipped from our US warehouse to United States, which is more faster than from aboard.

2-9 working days to: USA

Terms of sales

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

About us

Your satis

faction is our ultimate goal. We work hard to earn your trust and future business. Our certified technicians have tested each item before shipping. The unit comes with 1 year limited warranty on all manufacturing defects.

a) If you receive a defective item, you may return it or ask for a discount. Please contact us within 14 days after you receive the package.

b) What you returned must be intact and in its original packaging as re? u. Customer is responsible for shipping costs of the returned item.

c) We will cover the cost of shipping back t with the shipping rate indicated in the registration page. We will send you a new unit or refund the full payment you paid.

Thank you.

Contact us

Business Hour

Business Hour: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

On Jun-23-21 at 00:47:18 PDT, seller added the following information: