-40%

TB6600HG Stepper Motor Driver For Nema17 / 23 / 34+ 5 Axis Breakout Board Kit

$ 76.07

- Description

- Size Guide

Description

Frist-SupplyWorld Shipping

Money Back Guarantee

TB6600HG Stepper Motor Driver For Nema17 / 23 / 34+ 5 Axis Breakout Board Kit

/7

Description

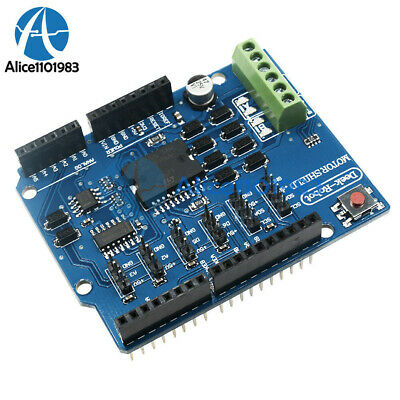

DIY CNC Kit Latest 3rd Generation Revolutionary 5 Axis Breakout Board Set(BCD-S)

+ 3 Pieces TB6600HG Stepper Driver Board Controller

Description

The latest 3rd generation breakout board has been upgraded to the intelligent, professional and industrial-level interface board set by re-designing the PCB board, embedding intelligent memory chip (professional version) and upgrading the external manual control tools (control pad and display panel). The re-designing the PCB board will make the breakout board control the microstep drivers more smoothly with lower noise. Actually, the 3rd generation breakout board set has two types of versions, one is the

standard version

, and another is the

professional version

. Compare to the standard version, the professional version mainly has two more functions than the standard version, one is the

"computer G-code recording function"

, and another is the

"manual programing function"

. Except these two functions, these two types of versions have no other differences.

With the embedded intelligent memory chip, the professional version of this 3rd generation 5 Axis breakout board can easily record MAXIMUM 4 Axis' (X, Y, Z, A Axis) G-code running on the CNC software

(e.g. Mach3, EMC2, KCAM4, etc..)

of the computer, and then rerun the recorded G-code to make the stepper motor work without the computer any more.

The TB1H is a high performance microstepping driver based on the latest original TOSHIBA high-efficiency TB6600HG IC. The TB6600HG adopts single-chip PWM bipolar sinusoidal chopper to ensure the low vibration and high efficiency. Moreover, the brand new design with BiCD0.13 (45V) process technology on the chipset also ensures maximum 5.0A output current and 45V output withstand voltage. Consequently, as long as the current range of the stepper motor is within

0.2-5 amps, all the 2 Phase or 4 Phase of Nema17, Nema23, Nema24 and Small-sized Nema34 stepper motors

will work perfectly with this new-type TB6600HG Stepper Driver.

In short, the qualities and functions of the new 3rd generation advanced 5 axis breakout board are revolutionized from the previous version. With this CNC Kit, you will get more benefits from the Kit on CNC work. Please purchuse this kit with confidence.

The item you are watching is the 5 Axis Standard Version (BCD-S), if you need the professional version, please feel free to contact with us.

Features

I. 3G 5 Axis Breakout Board

High performance, cost-effective.

To manually control the stepper motor, both of the standard and professional drivers have been equipped with the display panel and control pad.

Automatically identify both of the computer and control pad, functions of the computer and control pad can be switched intelligently for each other without any interference.

Display panel can

real-time trail the running path of G-Code

on the computer or input by the control pad, and then completely and synchronously display the changing of MAXIMUM FOUR axis'(X, Y, Z A axis etc.) values on its screen, it is

completely synchronous

with the values’ changing on the FOUR coordinates of Mach3.

Automatically finish Tool-settings

on X, Y, Z Axis via the control pad, without the support of the computer.

Both of the standard version and professional version are compatible with the Mach2, Mach3(Default Software),

LinuxCNC(EMC2), KCAM4 CNC Software

, etc.. Besides, the professional version also can automatically trail the path running path of G-Code from the CNC software (e.g. Mach3, EMC2, KCAM4, etc.) of the computer and record the G-code into the memory chip; Easy to repeatedly run the G-code to control the stepper motors without computer.

The professional version also supports manual programming via the control pad, as long as input the required values on one axis and record them in the memory chip of the driver, and then run these recorded values to drive the axis to make linear motion, widely used on RBI machine, Conveyor and so on.

Two ways to get power, 5V DC power supply or USB port to get power from PC directly.

Compatible with all the 2 phase, 3 phase and 4 phase microstep drivers in the market.

Automatic circuit protections function when the wirings between the breakout board and microstep drivers are incorrect.

With

Relay output control interface

, available to control the spindle motor, air pump, water pump, etc.

5-axis work LED display, visually display the working condition of the stepper driver controller.

5 Types of input control in manual control interface, to set

Limit, Estop, Midpoint-Setting, Cutter-presetting/Tool.

II. TB6600HG Stepper Driver Board Controller

High performance, cost-effective.

Automatic idle-current reduction.

Supply voltage up to

45V DC

.

Output current up to

5.0A

.

Suitable for 2-phase and 4-phase motors.

High speed optoelectronic isolation signal input.

Single-chip PWM bipolar sinusoidal chopper ensures low vibration and high efficiency.

1, 2, 4 (New Mode), 8, 16 adjustable microstep control, motors run more precisely and smoothly.

Equipped with the 3rd generation of breakout board, display panel and control pad to control the motor manually.

Cooling Aluminium Box Design for Cooling, and protect the driver board from being damaged by dirt, dust or other liquids.

Overload, overcurrent, overheat, overvoltage and undervoltage protection to avoid damaging your computer and devices.

Application

Suitable for any small-and-medium automatic equipment with CNC controller, such as X-Y-Z tables, labeling machines, laser cutters, engraving machines, and pick-place devices.

Suitable for a wide range of stepping motors, from NEMA size 17 to 34.

For advising, such as brand, architechture mould, badge, nameplate, display boards, doorplate, furniture decoration, etc..

For processing various pattern mould.

Power Supply Selection

12~24V DC power supply for Nema 17 stepper motors.

24~36V DC power supply for Nema 23/24 stepper motors.

36~45V DC power supply for Nema 34 stepper motors.

Output current of the power supply must exceed the sum of motor rated current.

Please SHUT DOWN the power before you plug or unplug the connectors to avoid burning up the board.

TB6600HG DIP-Switch Settings

I. DIP-Switch Instructions

II. DIP-Switch Settings Diagram

Output Current

SW1

SW2

SW3

0.2A

ON

ON

ON

0.6A

OFF

ON

ON

1.2A

ON

OFF

ON

1.8A

OFF

OFF

ON

2.5A

ON

ON

OFF

3.3A

OFF

ON

OFF

4.2A

ON

OFF

OFF

5.0A

OFF

OFF

OFF

Microstep Mode

SW4

SW5

SW6

N/A

ON

ON

ON

1(Full Step)

OFF

ON

ON

2

ON

OFF

ON

2

OFF

OFF

ON

4

ON

ON

OFF

8

OFF

ON

OFF

16

ON

OFF

OFF

N/A

OFF

OFF

OFF

Interface Instructions

(3G 5 Axis Breakout Board)

(TB6600HG Stepper Driver)

Connection Diagrams

(Breakout-Board-Wiring)

(TB6600HG-Wiring)

Specifications

Electrical Specifications of Breakout board

Input Voltage

5V DC via power adapter or directly get power from PC via USB port

Version Type

Standard version

Drive type

Pulse + Direction + Enable Signal Control

Suitable Microstep Driver

2 Phase, 3 Phase, 4 Phase Microstep Driver (M542/M542H/MA860H/3MA2290 etc.)

Net weight

170g (Breakout Board + Display Panel)

Dimensions

110*110*25mm

Operationg Environment & Other Specifications of Breakout Board

Cooling

Natural Cooling or Fan Forced cooling

Operating Environment

Environment

Avoid dust, oil fog, corrosive gas

Ambient Temperature

0 °C ~ 50°C (32°F ~ 122°F)

Humidity

40%RH ~ 90%RH

Operating Temperature

70°C (158°F) Max

Storage Temperature

-20 °C ~ 65°C (-4°F ~ 149°F)

Total Weight

Approx. 275g (Breakout Board + Control Pad + Display Panel)

Electrical Specifications Of TB6600HG Stepper Driver

Input Voltage

12V ~ 45V(Peak) DC

Output Current

0.2A ~ 5.0A (Peak)

Drive Type

Pulse + Direction + Enable Signal Control (Single-Chip PWM Bipolar Sine Chopper)

Suitable Motor

Nema17, Nema23, Nema24, Small-sized Nema34 (Rated current: 0.2A-5.0A)

Net Weight

250g

Dimensions

105*85*35mm

Operationg Environment & Other Specifications Of TB6600HG Stepper Driver

Cooling

Natural Cooling or Fan Forced cooling

Operating Environment

Environment

Avoid dust, oil fog, corrosive gas

Ambient Temperature

0 °C ~ 50°C (32°F ~ 122°F)

Humidity

40%RH ~ 90%RH

Operating Temperature

70°C (158°F) Max

Storage Temperature

-20 °C ~ 65°C (-4°F ~ 149°F)

Total Weight

Approx. 300g

Content

3 x 1 Axis TB6600HG Microstep Driver Board (TB1H)

1 x 3G 5 Axis Breakout Board (

Standard Version

)

1 x Control Pad (

Standard Version

)

1 x Display Panel (

Build-in Breakout Board

)

1 x DB25 LPT Parallel Cable

1 x USB Power Cable

1 x CD Driver

Shipping

Payment

Service

Estimated Delivery Time

(Subject to Stock Availability)

Country/Region

Standard

(Business Days)

Express

(Business Days)

USA, Canada

5 - 10

3 - 5

Australia, New Zealand, South Asia, East Asia

7 - 12

3 - 5

UK, France, Germany and Other EU Countries

(excluding Italy)

7 - 15

4 - 6

South America, Italy, Other Countries/ Regions

15 - 25

varying

We sell items to most countries of the world. To provide the most satisfying shipping experience, your order may be allocated to and processed in the best-match fulfillment center.

Remarks

• Usually, we dispatch your order within

ONE WORKING DAY

upon receipt of full payment when stock lasts.

• Above estimated delivery time is not guaranteed. However, 95%+ parcels are delivered within the reference time.

•

For fixed-time delivery or any special needs

, please do contact and confirm with us BEFORE placing order.

Safe and Easy Payment

PayPal

• We accept PayPal (Allows you to pay by credit cards, debit cards or echecks securely with

NO surcharge

)

• If you have difficulty in payment with PayPal, please do contact us for alternative payment solutions.

Remarks

• Payment is required

within 5 days

after auction ends.

• All sales are final. Shipping and handling charges are not negotiable.

• Your

PayPal shipping address will be used for delivery BY DEFAULT

unless otherwise informed.

• Please double-check to make sure your PayPal shipping address is correct before making payment.

Satisfaction Guaranteed

30 Days Money Back Guarantee

If you are not satisfied with the item purchased from us. Please contact us in writing (e.g. e-mail, eBay message)

within 30 days

of receipt of goods for return & refund guidance.

Free Replacement

If you receive a not-as-described (e.g. defective, incorrect, part missing) item, please contact us upon receipt of the item. We will arrange a replacement as soon as the case is confirmed.

12 Months Supplier Warranty

We provide

ONE YEAR warranty

on this product from date of purchase. If your item has any warranty issues, please contact us for a satisfying solution.

Requirements

• All qualified return/replacement must be guided by us. We may not accept your return without communication in advance.

• Any customs fee, handling charges, postage and insurance incurred in return/replacement are on customer's cost.

Agreement

: By placing an order, you acknowledge that you have accepted the terms and conditions of sale. You are welcome to contact us with any questions.

Image Gallery

Description

Specification

What's In

Service